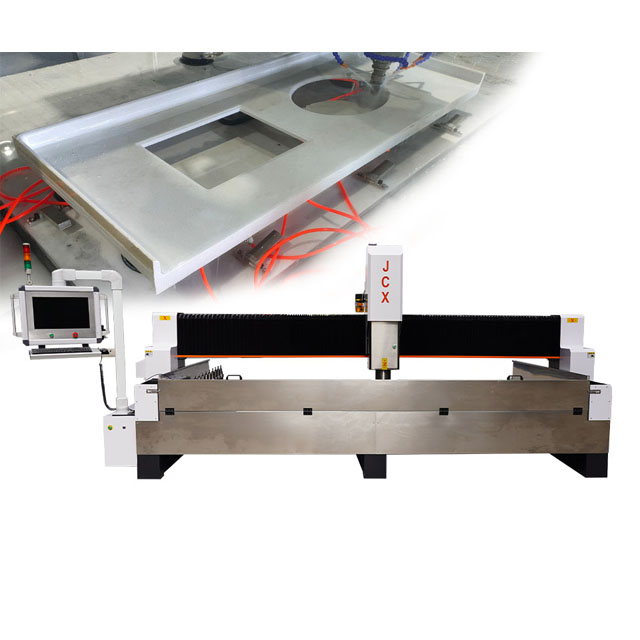

In the dynamic world of stone fabrication, the 3013 Automatic CNC Countertop Processing Center has emerged as an indispensable workhorse, seamlessly integrating cutting, milling, grinding, polishing, and sculpting capabilities into a single, high-performance system. Designed to tackle the diverse demands of modern countertop projects, this advanced machine combines five-axis precision with intelligent automation, empowering workshops to transform raw stone into functional masterpieces with unprecedented efficiency and artistry.

Surgical Precision in Cutting Complex Shapes

The 3013 Automatic CNC Countertop Processing Center redefines cutting precision, particularly for intricate countertop designs. Its high-speed diamond blades, paired with a 0.01mm-accuracy positioning system, effortlessly execute curved edges, sink cutouts, and irregular shapes. For example, a commercial project in New York required crafting 100+ quartz countertops with integrated drainboards and waterfall edges. The machine’s adaptive cutting algorithm optimized blade speed based on material density, completing each slab 50% faster than traditional methods while eliminating chipping—a critical advantage for high-value materials like Calacatta marble.

Artistic Milling for Custom Edge Profiles

The limitations of standard edge designs are gone.The 3013 Automatic CNC Countertop Processing Center features a multi-spindle milling module that can replicate classic profiles (e.g., ogee, bullnose) or create entirely unique geometries. A standout example is a residential project in Sydney, where the machine milled a “double-cove” edge— a complex concave curve—into 20mm-thick sintered stone countertops. The result? A seamless, luxury finish that matched the client’s mid-century modern aesthetic, achieved with zero manual adjustments and 30% less material waste than traditional routing.

Gallery-Quality Grinding and Polishing

The machine’s grinding and polishing capabilities elevate stone surfaces to museum standards. Equipped with diamond abrasives and variable-speed control, it transitions from rough grinding (80-grit) to (mirror-like 3000-grit) in a single automated pass. A case study with a granite fabricator in Brazil demonstrates this prowess: the team used the 3013 Automatic CNC Countertop Processing Center to refine 500m² of outdoor kitchen countertops with a “leathered finish”—a subtle, anti-slip texture. The machine’s adaptive pressure control ensured uniform results across all slabs, a feat nearly impossible with manual techniques.

From residential kitchens to commercial lobby installations, the 3013 Automatic CNC Countertop Processing Center proves that precision, speed, and creativity can coexist. Its ability to handle every stage of countertop production—from rough cutting to artistic sculpting—makes it a cornerstone of modern workshops. As the demand for bespoke, high-quality surfaces grows, this machine stands as a testament to how innovation in CNC technology is shaping the future of stone craftsmanship.